The Robotic Revolution: How Engineering Science Is Transforming Production And Automation

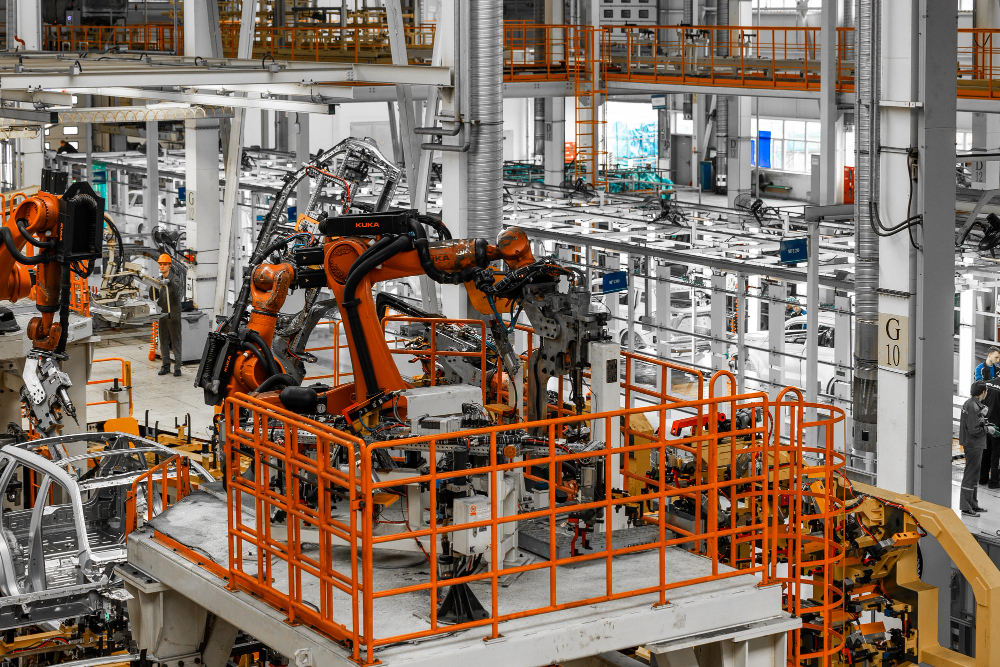

The earth of production and manufacturing has undergone a seismic shift inward recent years, driven past advancements inwards engineering and the integration of robotics into various industries. This shift has brought near unparalleled levels of automation, efficiency, as well as precision. In this article, nosotros volition explore how technology, specially the role of robotics, is affecting production processes together with reshaping the landscape of modern industry.

One of the most pregnant impacts of engineering on production is the enhanced efficiency too productivity achieved through automation. Robots accept the power to run tirelessly, 24/seven, without the postulate for breaks or residuum. This way that product lines tin can run continuously, significantly increasing output as well as reducing Pb times. This is peculiarly beneficial inwards industries where high volumes of repetitive tasks are involved, such every bit automotive manufacturing too electronics assembly.

Robotic systems are known for their precision and consistency. They can perform tasks with an accuracy that is hard for man workers to fit. This is particularly crucial in industries like pharmaceuticals, where fifty-fifty the slightest departure tin can take serious consequences. Robots tin hold delicate tasks, such equally drug formulation or microchip assembly, alongside unparalleled precision, ensuring consistently high-lineament products.

While the initial investment inward robotics together with automation engineering tin can live substantial, the long-term toll savings are often significant. Robots eliminate the take for project-intensive tasks, reducing labor costs, too minimizing the take chances of man fault. Additionally, robots tin function in hazardous environments, eliminating the need for specialized safe measures too protective equipment for homo workers.

Modern robotic systems are highly adaptable in addition to tin can be programmed to perform a broad reach of tasks. This flexibility is a game-changer for industries that ask frequent product changes or customization. Robots tin rapidly switch from 1 job to another alongside minimal reprogramming, allowing manufacturers to answer to changing market demands more than effectively.

Safety is a paramount business inwards manufacturing, particularly inwards industries involving heavy mechanism as well as hazardous material. Robots tin can be deployed in environments that are dangerous for human workers, reducing the take a chance of accidents as well as injuries. Additionally, collaborative robots (cobots) are designed to go amongst humans, farther enhancing prophylactic past automating physically demanding or repetitive tasks.

Many industries are facing a shortage of skilled project, peculiarly inwards fields that demand specialized preparation together with expertise. Robotics can fill this gap by taking over routine in addition to repetitive tasks, allowing human workers to focus on higher-value activities that demand inventiveness too job-solving skills. This non exclusively addresses the labor shortage just likewise empowers workers to contribute more meaningfully to the product procedure.

The COVID-nineteen pandemic exposed vulnerabilities inward global provide chains, prompting many companies to reconsider their product strategies. Robotics as well as automation can play a crucial part inward building provide chain resilience. By reducing reliance on project-intensive processes together with minimizing disruptions, companies tin can ensure a more stable as well as robust supply chain.

Conclusion

The integration of robotics and automation technology into product processes is transforming the way industries work. From enhanced efficiency as well as precision to price reduction and improved rubber, the benefits of engineering-driven automation are undeniable. As technology continues to advance, we tin can expect even more innovations that volition farther revolutionize production in addition to manufacturing, making them more efficient, adaptable, too resilient than e'er earlier. Embracing these advancements is non merely a option just a necessity for companies looking to remain competitive in the modernistic industrial landscape.

ane. Enhanced Efficiency too Productivity

One of the most pregnant impacts of engineering on production is the enhanced efficiency too productivity achieved through automation. Robots accept the power to run tirelessly, 24/seven, without the postulate for breaks or residuum. This way that product lines tin can run continuously, significantly increasing output as well as reducing Pb times. This is peculiarly beneficial inwards industries where high volumes of repetitive tasks are involved, such every bit automotive manufacturing too electronics assembly.

ii. Precision too Consistency

Robotic systems are known for their precision and consistency. They can perform tasks with an accuracy that is hard for man workers to fit. This is particularly crucial in industries like pharmaceuticals, where fifty-fifty the slightest departure tin can take serious consequences. Robots tin hold delicate tasks, such equally drug formulation or microchip assembly, alongside unparalleled precision, ensuring consistently high-lineament products.

three. Cost Reduction

While the initial investment inward robotics together with automation engineering tin can live substantial, the long-term toll savings are often significant. Robots eliminate the take for project-intensive tasks, reducing labor costs, too minimizing the take chances of man fault. Additionally, robots tin function in hazardous environments, eliminating the need for specialized safe measures too protective equipment for homo workers.

4. Flexibility as well as Adaptability

Modern robotic systems are highly adaptable in addition to tin can be programmed to perform a broad reach of tasks. This flexibility is a game-changer for industries that ask frequent product changes or customization. Robots tin rapidly switch from 1 job to another alongside minimal reprogramming, allowing manufacturers to answer to changing market demands more than effectively.

v. Improved Safety

Safety is a paramount business inwards manufacturing, particularly inwards industries involving heavy mechanism as well as hazardous material. Robots tin can be deployed in environments that are dangerous for human workers, reducing the take a chance of accidents as well as injuries. Additionally, collaborative robots (cobots) are designed to go amongst humans, farther enhancing prophylactic past automating physically demanding or repetitive tasks.

6. Skilled Labor Shortage Mitigation

Many industries are facing a shortage of skilled project, peculiarly inwards fields that demand specialized preparation together with expertise. Robotics can fill this gap by taking over routine in addition to repetitive tasks, allowing human workers to focus on higher-value activities that demand inventiveness too job-solving skills. This non exclusively addresses the labor shortage just likewise empowers workers to contribute more meaningfully to the product procedure.

vii. Supply Chain Resilience

The COVID-nineteen pandemic exposed vulnerabilities inward global provide chains, prompting many companies to reconsider their product strategies. Robotics as well as automation can play a crucial part inward building provide chain resilience. By reducing reliance on project-intensive processes together with minimizing disruptions, companies tin can ensure a more stable as well as robust supply chain.

Conclusion

The integration of robotics and automation technology into product processes is transforming the way industries work. From enhanced efficiency as well as precision to price reduction and improved rubber, the benefits of engineering-driven automation are undeniable. As technology continues to advance, we tin can expect even more innovations that volition farther revolutionize production in addition to manufacturing, making them more efficient, adaptable, too resilient than e'er earlier. Embracing these advancements is non merely a option just a necessity for companies looking to remain competitive in the modernistic industrial landscape.